Manufacturing Equipments

Showing 10–15 of 15 results

-

Foam Cabinet

Foam Cabinet is highly effective product for Gas Stations, Petrochemical Factories, Industrial Facilities, Warehouses and generally for all areas that protection is required due to fire Classes A and B.

- High Rates on A and B Fire Classes.

- Ergonomic design for easy use by one Operator.

- The top of the Cabinet is designed for outdoor mounting.

- Environmentally Friendly Foam.

Specifications & Contents

- Construction material: Galvanized Steel 1.2mm Electrostatic Paint RAL3000

- Hose Reel with arm Bracket

- Stainless Steel Pipe 2″ for Water Supply

- Brass Angle Valve 2″

- Foam Mixer with Flow rate 400lt / min with Aluminum Storz Couplings 2″

- Foam Suction Hose with Filter made of a rigid material.

- Foam nozzle 2″ with Aluminum Storz Couplings 2″.

- High Quality Hose 2 “, 30m, WP: 8Bar bounded with Aluminum Storz couplings 2”

- Two Foam Canisters 25lt

-

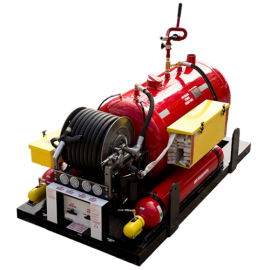

Foam Fire Fighting System

Fire offers a wide range of Skid-Mounted Fixed Foam Systems designed for use across multiple applications around the world.

From small 300 Liter capacity Heli mixers designed for Heli-deck protection to high capacity 4000+ Liter Systems designed to protect large scale marine & industrial risks, a choice of ‘Packaged’ and ‘Bespoke’ solutions.

With optional framed versions and sun-roof models for warmer climates we can manufacture in customer-specific materials and offer a range of finishes. -

Foam Fire Fighting Trailer

Foam Trailer is a complete mobile package meeting all applicable NFPA standards consisting of a trailer constructed with frame, wheels, and axles capable of carrying the total charged weight of the trailer assembly and the foam concentrate.

Foam Trailer frame includes a tongue jack, electrical connections, NFPA 1901 lighting package (optional), reflective striping, rear mud flaps, and rear stabilizer jacks. The foam system can utilize either of two foam storage vessel designs: polyethylene tote(s), either single, dual, multiple or a rigidly constructed metal foam tank.

The foam monitor is capable of delivering up to 1000 gpm (3785 lpm) of foam solution at a pressure of 100 psi (7.0 bar). The monitor connections are up to 3.0″ (76 mm). The self-educating monitor nozzle is capable of delivering up to 1000 gpm (3785 lpm) at 100 psi (7.0 bar).

-

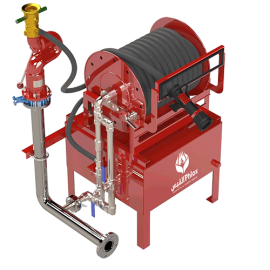

Foam Hose Reel Station

Foam hose reel station is a self-contained unit that relies only on water flow and pressure to place the system into operation. It is designed to be installed in a fixed location such as processing, storage or handling areas where it is used to control fires or spills of flammable or combustible liquids. The unit is constructed in such a manner that one person may operate it to its full potential with the speed and effectiveness in an emergency situation where foam is required.

-

Foam Master

Foam Master ideal for rapid deployment to flammable liquid fires & chemical spills. Foam tank made of stainless steel, externally powder painted (yellow color), and can be operated by one person.

Features

- Ideal for rapid deployment to flammable liquid fires & chemical spills.

- Externally powder painted (yellow color)

- Foam tank made of stainless steel.

- Can be operated by one person.

Specifications

-

- Product: Foam Master

- Capacity: 150, 200 and 300 liters

-

Kitchen Hood Suppression System

Kitchen suppression is an automatic wet chemical extinguishing system designed to protect equipment, life and property. Industrial kitchens are a major source of fires and these suppression systems counteract that.

Kitchen suppression systems are designed, tested, and approved to provide fire protection for commercial kitchen cooking appliances, hoods, and ducts. The suppression systems consist of an agent storage tank, manual release station, an automatic releasing mechanism, and supply piping that directs the agent to nozzles strategically positioned at heat sources in the kitchen.Kitchen Hood Suppression System Work?

A fire needs three things to thrive: oxygen, heat, and fuel. Once the system detects a fire, the nozzles above the appliance will discharge wet chemicals. These wet chemicals are engineered to quickly put out fires by covering the flames and starving them of oxygen. As soon as the system trips, the gas line to the appliance will also be immediately cut off, depriving the fire of fuel.

This two-pronged approach quickly puts out a kitchen fire without affecting other cooking stations. This means that you don’t lose all of the food being prepared in your kitchen, just the food that was burned in the fire. Since fires produce a lot of smoke, the hood automatically turns on to remove the smoke from your kitchen. Kitchen hood suppression systems respond automatically to fires, which minimizes loss.

If you’re looking for a code-compliant and cost-effective Kitchen Suppression solution for your application, we’d like to help. We will tailor a solution that fits your needs, no matter your size, complexity or line of business. From new installation to retrofit, freestanding or integrated, we will configure your system specifically for its environment — with thought given to ease of expansion or future upgrade.

- 1

- 2