Foam Fire Fighting System

Foam Fire Fighting System in UAE

At first to give a brief about Foam System:

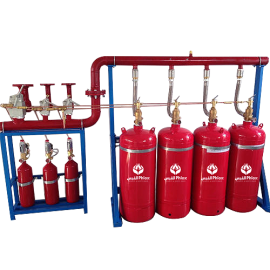

The “foam” in foam fire suppression systems is an extinguishing agent that can extinguish flammable or combustible liquid by cooling and separating the ignition source from the surface. The foam also suppresses and smothers fire and vapors alike and prevents reignition.

Foam systems are primarily water systems with either air or nitrogen injected into the system. Mechanical equipment includes compressors, drillstring floats, a rotating control device, a separator, and a flare. The gas source (compressor, etc) is a major cost in this group.

The foam blankets the fuel surface smothering the fire. The foam blanket separates the flames/ignition source from the fuel surface. The foam cools the fuel and any adjacent metal surfaces.

Description:

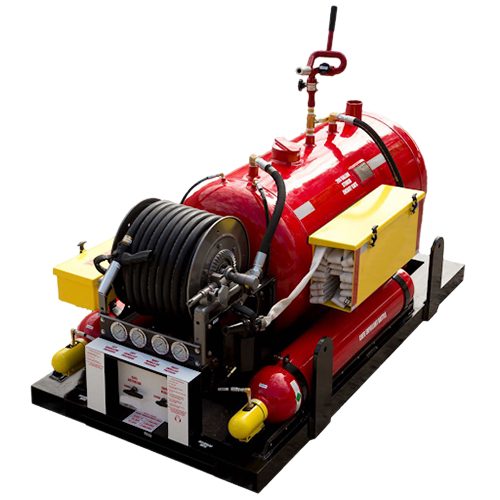

WE offers a wide range of Skid-Mounted Fixed Foam Systems designed for use across multiple applications around the world. including, from small 300 Liter capacity Heli mixers designed for Heli-deck protection to high capacity 4000+ Liter Systems designed to protect large scale marine & industrial risks, a choice of ‘Packaged’ and ‘Bespoke’ solutions.

With optional framed versions and sun-roof models for warmer climates we can also manufacture in customer-specific materials in addition to offer a range of finishes.

Luckily, PHLOX Security & Safety Equip. LLC is here to help you with your fire-related equipment needs.

Finally, We are a leading expert in fire-safety systems and installation that would guarantee the safety of your establishment, We have a wide range of products for different fire-preventive measures needed, and we have the best and cost-effective Foam Fire Fighting System in UAE.