Manufacturing Equipments

Showing 1–9 of 15 results

-

CAFS Trailer System

Burner Fire Control has been again selected to provide its 200 Gallon Compressed Air Foam Trailer Unit for emergency response for operations in the Arabic Gulf countries, Ghana, Africa. The CAFS 200 HD Trailer System provides self-contained and mobile capabilities to address potential surface hazards within the operations and surrounding areas. The Unit was shipped with Class A and B foam concentrate for mitigation of potential structural and hydrocarbon hazards.

-

Clamping Device

Pneumatic clamping device for CO2- and powder extinguishers with pneumatic clamping cylinder.

TECHNICAL DATA model PT (No. 100 450) Dimensions (l x w x h) approx. 300 x 850 x 1000 mm Clamping surface (Ø) 80 – 220 mm Compressed-air 6 – 8 bar Color blue Optional available at extra charge:

- Equipped with adjustable clamping pressure (used for powder extinguisher)

-

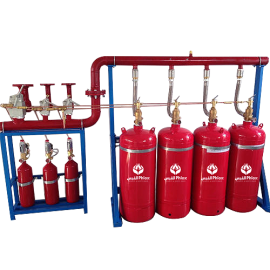

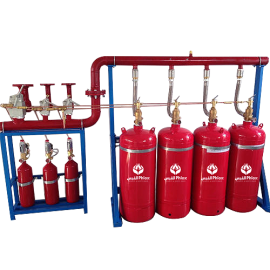

Clean Agent Fire Suppression Systems

There are three common clean agent fire suppression systems to choose from, including FM-200, 3M™ Novec™ 1230, and Inergen Clean Agent Fire Suppression System. All systems use gases that are safe for the environment and humans, but they utilize different ways of suppressing a fire.

- The FM-200 system is stored as a liquid and vaporizes when discharged. The system displaces the oxygen around a fire, but heat absorption is its primary extinguishing capability.

- The Inergen system uses inert gases- nitrogen, argon, and carbon dioxide- to reduce the oxygen level and suppress the fire. While carbon dioxide is included, the concentration is safe for humans and the environment. Once the Inergen concentration is discharged, it returns to the atmosphere in its natural state.

- The 3M™ Novec™ 1230 system uses a liquid that is vaporized when discharged, similar to the FM-200 system. However, unlike the FM-200 which suppresses the fire by heat absorption or cooling, the 3M™ Novec™ 1230 displaces the oxygen around a fire to suppress it.

CO2 Fire Suppression Systems

If a building has rare or little occupancy, they may use a CO2 fire suppression system instead of a clean agent system. These systems are only used in buildings with very low occupancy, as carbon dioxide can result in health risks for anyone exposed, and can even be deadly. Clean agent systems are much more common, as they use gases they aren’t harmful to humans.

3 Main Parts Of The System

A clean agent fire suppression system is commonly made up of three parts: smoke detectors, the control panel, and notification devices. The smoke detectors work as usual and will detect a fire before it has time to escalate into an uncontrollable event. The smoke detector will send a signal to the control panel, which then alerts the notification devices and activates the release device to suppress the fire. The notification devices are there to warn occupants of the fire, and alert people in the area when the clean agent is about to be released.

-

CO2 Extinguisher Refilling Machine

Power: 1.1 KW – 220 V/ 50 Hz

Refilling Speed: ≥ 3 KG/Min

Refilling Range: 1~48 KG

Weight: 53 KG

Machine Size: 530×430×430 mm

Carbon dioxide(Co2) extinguisher refilling machine is newly developed based on. It is suitable for all kinds of portable Co2 fire extinguishers. It is no need to heating and refrigerating, but can refill the Co2 fire extinguisher directly from big bottle.

-

Co2 Fire Extinguishers Trolley

20kg co2 fire extinguishers are generally used for industrial fires and are ideal for B, C & E Fires. It is an alternative clean agent for 1211 halon application, purity of our co2 gas reaches 99.98%. Co2 is electrically non-conductive and therefore safe for fighting fires in electrically powered equipment. Co2 extinguishers are made of seamless carbon steel materials to withstand high storage pressure. Co2 is colorless gas which reduces the oxygen of the air around the fire, the co2 gas does not deteriorate with storage or freeze in a container. Snow horn with a built-in nozzle specially designed to fit our valve to give the most efficient fire suppression. Manufactured according to BSEN3, Available in black and red color and Approved by UAE civil defense

-

Dry Powder Fire Extinguisher Filling Machine

Dry Powder Fire Extinguisher Filling Machine is a new model improved by our factory. It can suck dry powder into the cylinder quickly by vacuum. It has several advanced features, such as small volume, easy movement, simple operation, and environmental protection. It is especially suitable for the filling, production, and maintenance of dry powder extinguisher and also suitable for filling various powder products. It is ideal equipment in the powder filling industry

-

Dry Powder Trolley

Wheeled Powder Fire Extinguisher 50KG is manufactured according to Directive 96/98/EC (MED) with modules B and D. As with portable extinguishers, wheeled units also have to comply with high standards to ensure their extinguishing capability (fire rating), quality and reliability. We at a.b.c. know how important it is to make the right choice in firefighting. Recently, a new European standard for wheeled extinguishers, EN 1866, was introduced. The a.b.c. wheeled extinguisher range has been the first in Europe to comply with this standard.

The wheeled units also carry the CE mark so the range can boast three quality guarantees: a.b.c. (ISO 9001), compliance with EN 1866 and the CE mark. The standard EN1866 defines important minimum levels of pressure retention, corrosion protection, operating temperatures and fire rating.

-

Fire Fighting Hydrant and Monitor

Water hydrant mounted on the pipe. Industrial safety equipment for extinguishing fire. Worker standing with monitor on background. Water supply industry or refinery plant extinguishing accessories. Fire protection equipment for oil and gas refinery factory. Water supply chain mounted on tube, mounted on monitor monitor, fixing water pipes and accessories.

-

Foam Bladder tank

Foam bladder tank is widely used in foam fire extinguishing system, such as chemical industrial enterprises, port and dock, large oil storage, airport oil storage, oil or fuel power plants, boiler room, dangerous goods storage, chemical warehouses and so on.

Foam bladder tank is made from tank, bladder, pressure-type proportioner, safety valves, control valves, level gauge and a lot of ancillary components.

The foam concentrate in the bladder can be used next time because it doesn’t contact with water.

Type of Proportioner: 1%, 3%, 6%.

Shape of tank: Horizontal or vertical.

Volume of tank: 500-15000L.

- 1

- 2